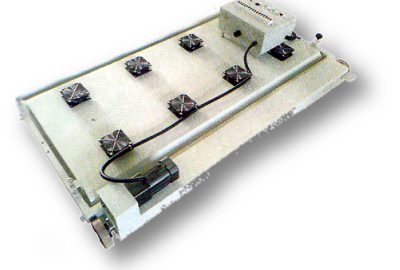

IR Drying Machine

Application:

The infrared drying tunnel has been designed to meet quality demands for finished product. The tunnel heats using medium waves infrared lamps that reach the emission levels required in a very short space of time, thereby reducing wait times for starting work, to a minimum. Rapid drying the solvent-based ink and products containing moisture.

Features:

- The speed can be adjusted between 0-20M/Min according to the requirement of products.

- Adopting the imported transmission belt, which is made of Teflon or stainless steel that can stand of high temperature, stably transmission, shock-free, no-noise.

- Adopt imported thermostat to ensure the stability and accuracy of temperature control.

- Can save space and improving working efficiency.

Technical Parameters:

| Model | TX-IR800 |

|---|---|

| Machine Size (L × W × H) | 8000 × 1200 × 1350 (mm) |

| Belt Width | 800 mm |

| Input Zone | 0.5 m |

| Drying Zone | 6 m (3section) |

| Cooling Zone | 1 m |

| Output Zone | 0.5 m |

| Speed | 0~10m/min |

| Max Temperature | 150 ℃ |

| Heating Light Power | 30 kw |

| Conveyor Motor | 1.5 kw |

| Fans Power | 2 kw |

| Total | 34Kkw (Working:12KW) 380V |

All information belongs to TAOXING