Beta

Application

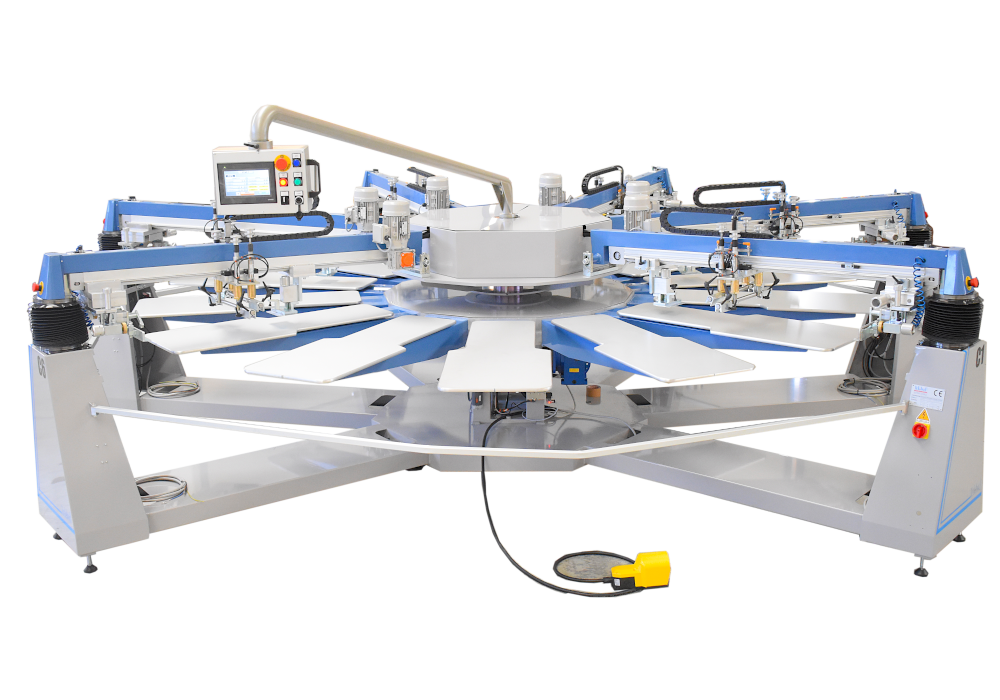

Automatic circular screen printing machine with flat frames available from 1 to 6 printing units with or without intermediate spaces for the insertion of the flash cure units. The machine is equipped with alveolar aluminum pallet and a central “touch-screen” control panel allows to program all the machine’s functions.

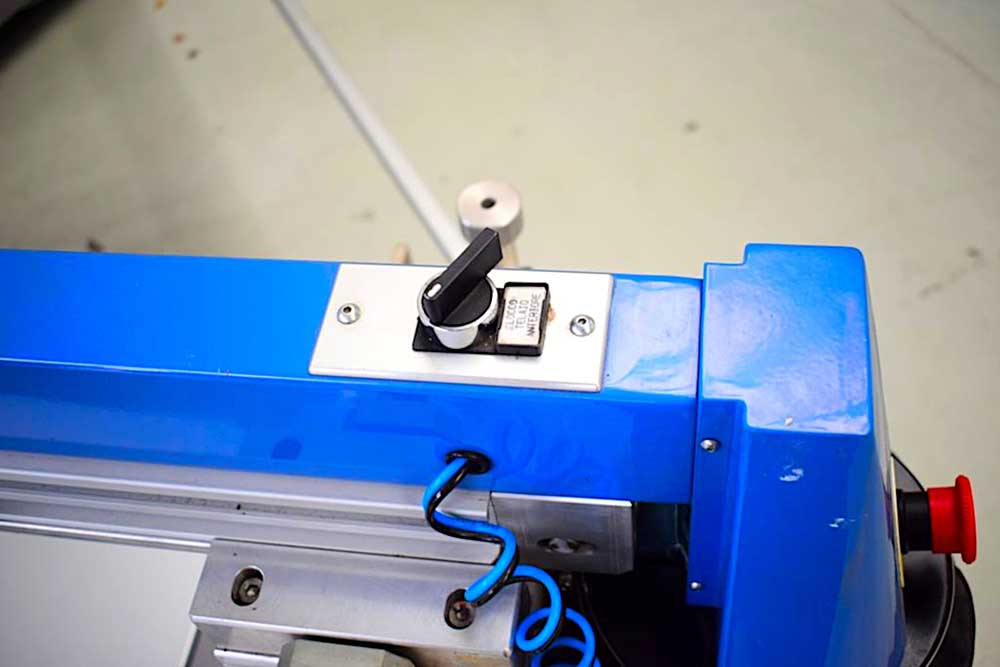

Beta simplified version of the Alfa model without renouncing the degree of precision guaranteed by a mechanical rotary table installed on both machines. Production speed and quality are the same in the two models, the only differences concern the controls and the methods for setting the machine parameters: in the Alfa model there is a panel on each station that allows you to manage the machine and set the station’s parameters, while for Beta model all the settings such as speed, number of passes, can be managed from a common panel that turn around the machine. Other differences are: in the Alfa model all the stations are independent while in the Beta model they go up and down all together even if they are not used, the cleaning lift is independent for the Alfa model while instead common for the beta model, rear frame block is manual for the Beta model while it is pneumatic with selector for the Alfa model.

Features

- Start and stop sequential automatic program

- Simultaneous lifting for each printing head

- Intermediate spaces between each printing unit where the flash-cure units can be installed

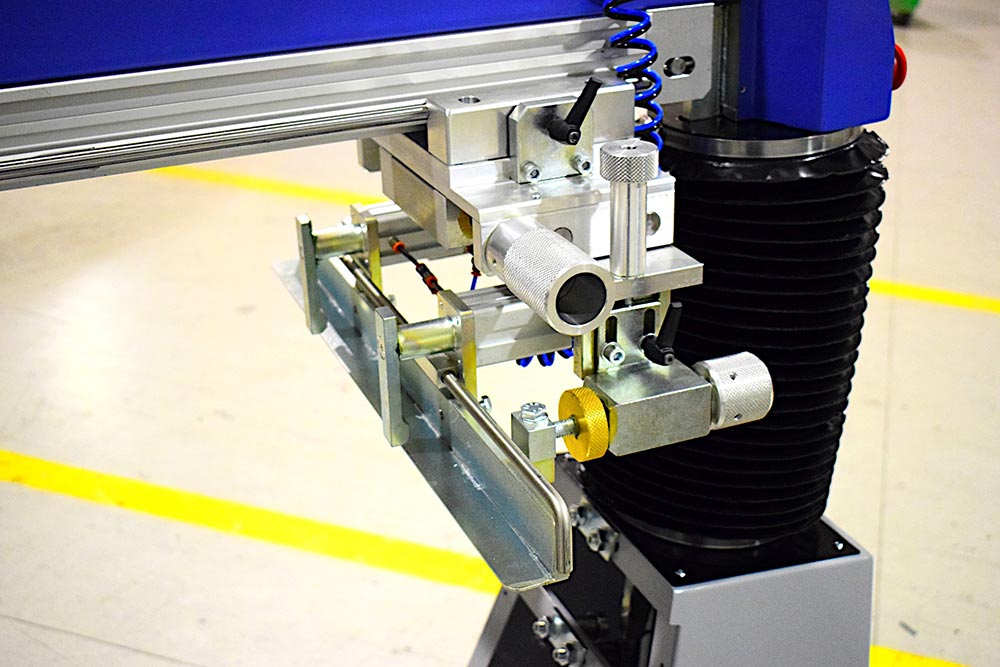

- Squeegee / flood bar pressure and angle adjustments independent, easy, fast and accurate to be operated

- Squeegee stroke individually adjustable for each printing unit

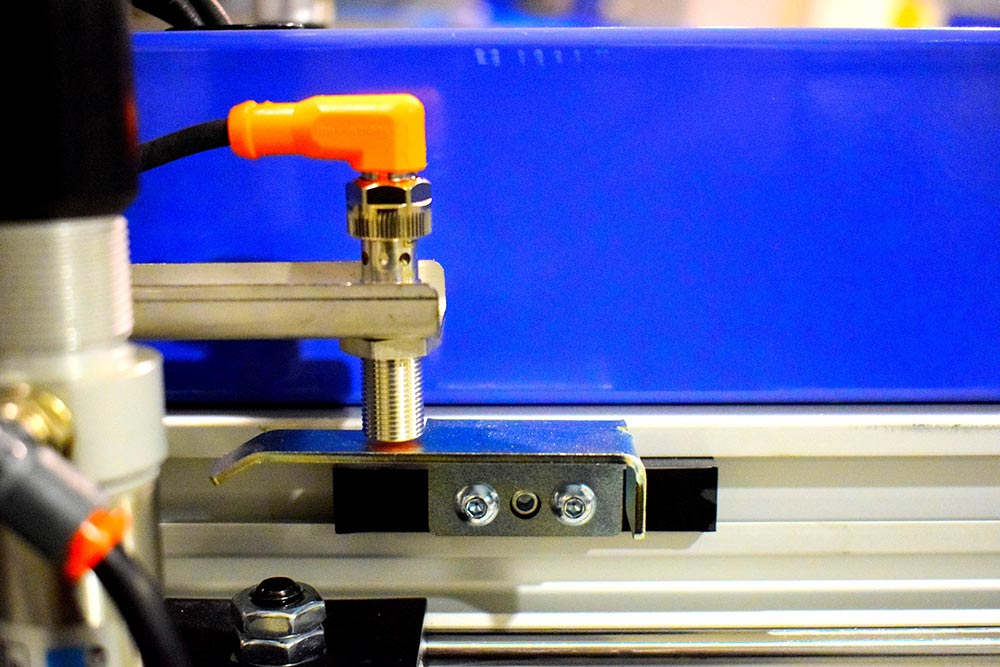

- Pneumatic screen locking system

- Honey-combed aluminium pallets featuring a high planarity

- Squeegee / flood bar motorization by AC motors – inverters – linear guides featuring exceptional performances and reduced maintenance. Accurate adjustments and total lack of vibrations.

- “Touch-screen” main control board, intuitively operated, endowed with integrated diagnostic system

- Programming function for multiple printing strokes for each garment, in case a high coating is required

- Sampling function, which allows to automatically print only a sample garment

- A wide range of intermediate flash-cure units is available

Technical Parameters:

| Model | N° Colors | N° of Printings | Print Size | Machine Diameter | Installed Power | Air Pressure | Air Consumption | Print Accuracy | Production Capacity |

|---|---|---|---|---|---|---|---|---|---|

| Beta 4/10 | 4 | 10 | 50×70 cm | 440 cm | 4 kw | 6-8 bar | 19 m3/h | ± 0.1 mm | 900 pcs/h |

| Beta 5/12 | 5 | 12 | 50×70 cm | 488 cm | 4.5 kw | 6-8 bar | 25 m3/h | ± 0.1 mm | 900 pcs/h |

| Beta 5/12 | 5 | 12 | 60×80 cm | 496 cm | 4.5 kw | 6-8 bar | 25 m3/h | ± 0,1 mm | 900 pcs/h |

| Beta 6/8 | 6 | 8 | 50×70 cm | 448 cm | 5 kw | 6-8 bar | 30 m3/h | ± 0.1 mm | 900 pcs/h |

| Beta 6/14 | 6 | 14 | 50×70 cm | 520 cm | 5 kw | 6-8 bar | 30 m3/h | ± 0.1 mm | 900 pcs/h |

| Beta 6/14 | 6 | 14 | 60×80 cm | 577 cm | 5 kw | 6-8 bar | 30 m3/h | ± 0.1 mm | 900 pcs/h |