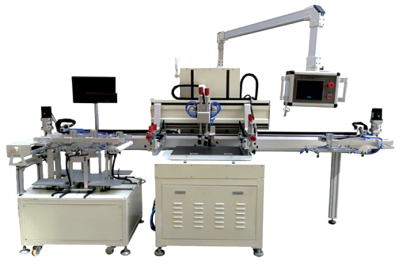

Graphite Coating Screen Printing For Plunger Piston Compressor

Application:

The unit is suitable for graphite coating of screen-printing for plunger/piston/compressor, which is high precision, wear resistance, coating evenly, and fully meet the standard. It can form high gloss and strong lubricating higher hardness film and it is lifelong.

Features:

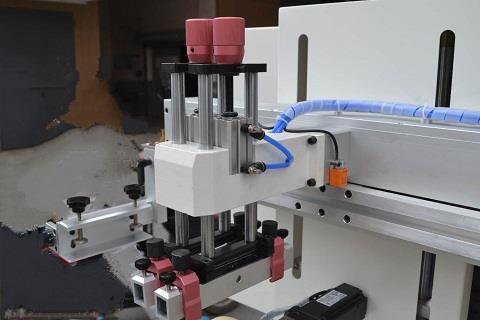

- Clean and sweep the machine before you are using, lubricate guide rails, guide pillars, bearings, and some other moving parts.

- The worktable is an important part for the printing quality and should protect it from being hit by hard objects when the machine is working, we should make sure that the ink, banana oil and other organic solvent would not drip onto the machine.

- Prevent the electrical control panel and keys from being damaged by banana oil and another solvent.

- Clean the dirt inside the oil mist assembler as soon as possible, avoid contamination into pneumatic components, to affect the normal work. Put lubricating oil into the oil mist assembler cup regular intervals.

- Loosen the tightening nuts before adjusting the flow-limiting valve.

- Turn off the power when you are off work, clean the screen.

Technical Parameters:

| Model | TX-500S | Max Printing Size | φ50 × 160 mm | |

|---|---|---|---|---|

| Max Printing Speed | 800 pcs/hr | Max Screen Frame | 700 × 350 mm | |

| Max Printing Area | 500 × 200 mm | Printing Length | ≤ 250 mm | |

| Pressure | 5 Bar | Voltage and Power | 220V 20W | |

| Gross Weight | 120 kg | Dimension | 960 × 900 × 1380 mm |