CTS Exposure Unit

Application:

The CTS is a vertical laser direct imaging exposure unit used in screen printing processes for various industries. High precision, high power, high speed and high efficiency.

Features:

- Maximum 800mm x 1200mm/31″ x 47″ exposure area

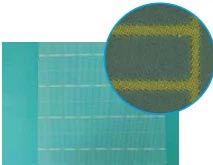

- Applicable for garment printing, label & packaging printing, PCB, optoelectronics and other industries

- Maximum 133 LPI image resolution

- 120 levels of controllable exposure power

- Real-time focusing with maximum focal depth of 4mm

- Maximum 3m/s output speed

- Integrated equipment

- Support TIFF, Gerber, DXF, BMP and other file formats

Advantage:

- Environment-Friendly: photographic film, developer and fixer are not required, which can effectively reduce chemical pollution.

- Low Cost: There are no special requirements for brands of emulsion, materials of sample, flatness of frame and types of mesh. The damaged laser can be replaced separately without expensive overall replacement.

- Diverse Application: textile printing, packing printing, ceramic printing, PCB solder mask printing, touchscreen printing, photovoltaic printing and photolithography printing.

- High Reliability: the laser module has ultra-long service life of more than 30,000 hours and has no attenuation for 10,000 hours. The MTBF (mean time between failure) of the whole machine is more than 10,000 hours.

- Customization: based on the high scalability of the technical route and the company’s mature IPD process, Antenna can quickly respond to customer’s customized service requirements, so that high-end customers in the industry have the most suitable plate making equipment.

- High Precision: optical resolution can reach to 2540 dpi.

- High Power: maximum exposure power is 150 mj/cm2. A 1,000 μm thick emulsion can be exposed.

- High Speed: maximum linear velocity is up to 6 m/sec. The total output time is less than 3 minutes.

- High Efficiency: the film alignment process is replaced by laser direct imaging. Accurate exposure positioning greatly improves the yield of plate making. A function of multi frame can output 2~3 images at the same time.

Technical Parameters:

| Model | CTS-80120M | CTS-1015M | CTS-1216M | CTS-1626M |

|---|---|---|---|---|

| Image Size | Maximum 800 × 1200 mm | Maximum 1000 × 1500 mm | Maximum 1200 × 1600 mm | Maximum 1600 × 2600 mm |

| Frame Size | Maximum 1100 × 1700 mm | Maximum 1350 × 2000 mm | Maximum 1350 × 2000 mm | Maximum 1850 × 3000 mm |

| Lasers | 128 | 160 | 192 | 256 |

| Noise | 70 db | 74 db | 74 db | 85 db |

| Speed | Less than 2.5 minutes | Less than 3.5 minutes | Less than 3.5 minutes | Less than 8 minutes |

| Process Mode | Pneumatic clamping , Vertical | |||

| Exposure Light | 405 nm laser | |||

| Interface | USB 2.0/3.0 | |||

| Resolution | 847/1270/2540 dpi | |||

| Repeatability | Less than 0.1 mm | |||

| Emulsion Type | Most kinds of emulsion | |||

| Emulsion Thickness | Maximum 1000 μm | |||

| Temperature | 21 (±3)℃ | |||

| Humidity | 50 (±10)% | |||

| Power Consumption | 800 w | 1000 w | 1000 w | 1500 w |

| Net Weight/Gross Weight | 925 kg / 1190 kg | 1200 kg / 1560 kg | 1200 kg / 1560 kg | 2500 kg / 2600 kg |

| Dimension | 2285 × 685 × 1690 mm | 2565 × 685 × 2050 mm | 2565 × 685 × 2050 mm | 3660 × 730 × 2380 mm |