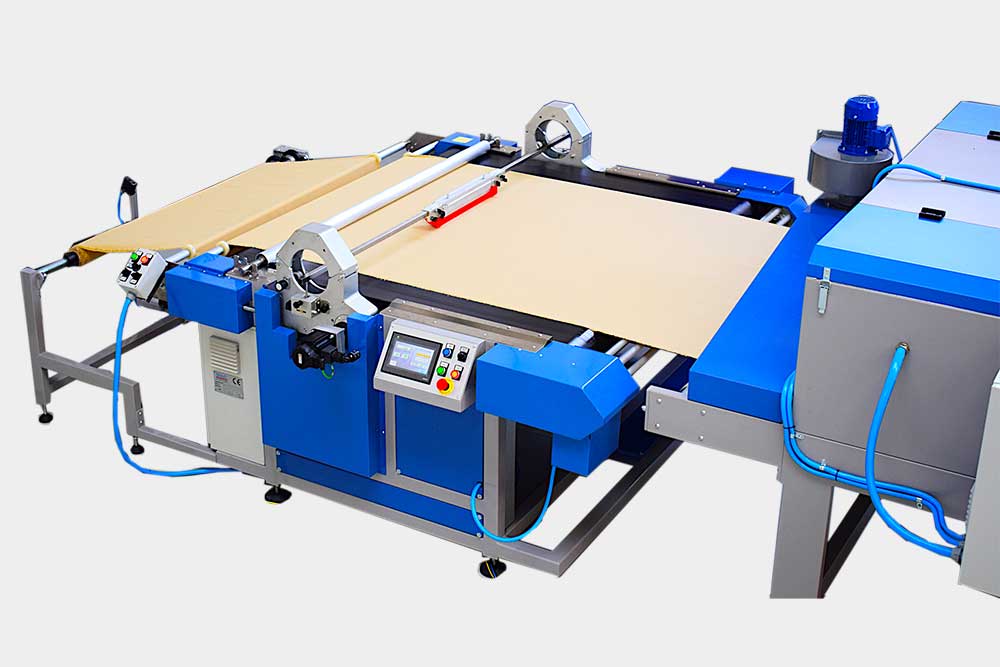

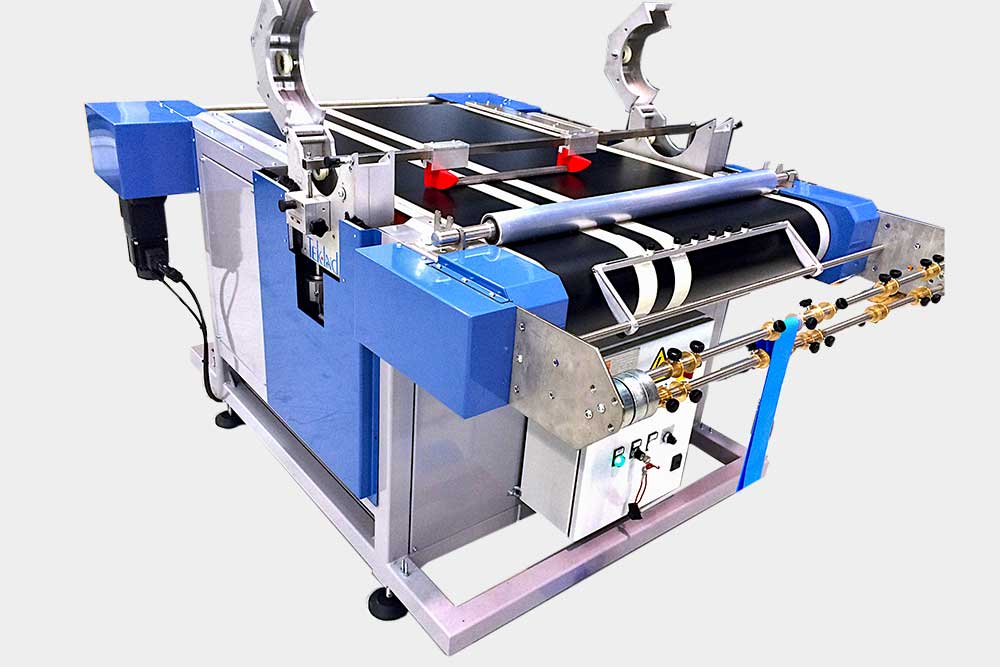

Rotoscreen Printing Line (Ribbon)

Application:

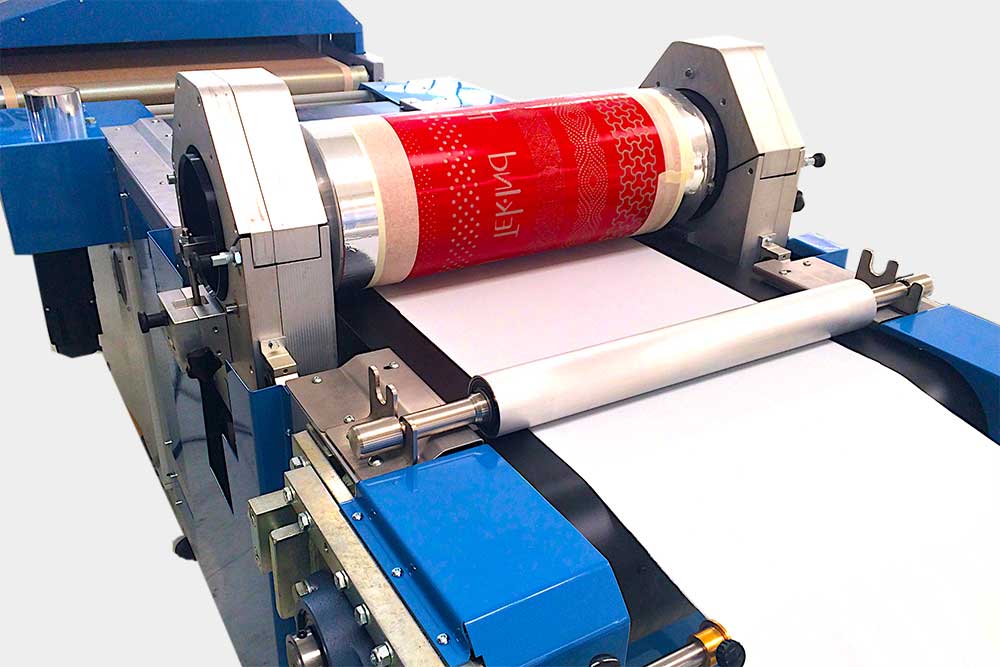

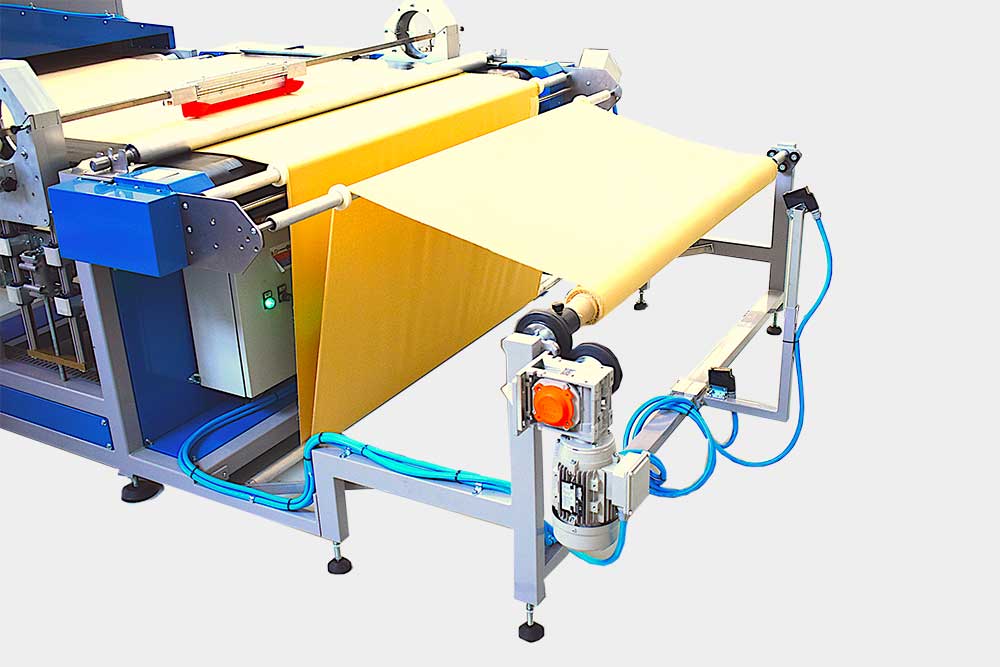

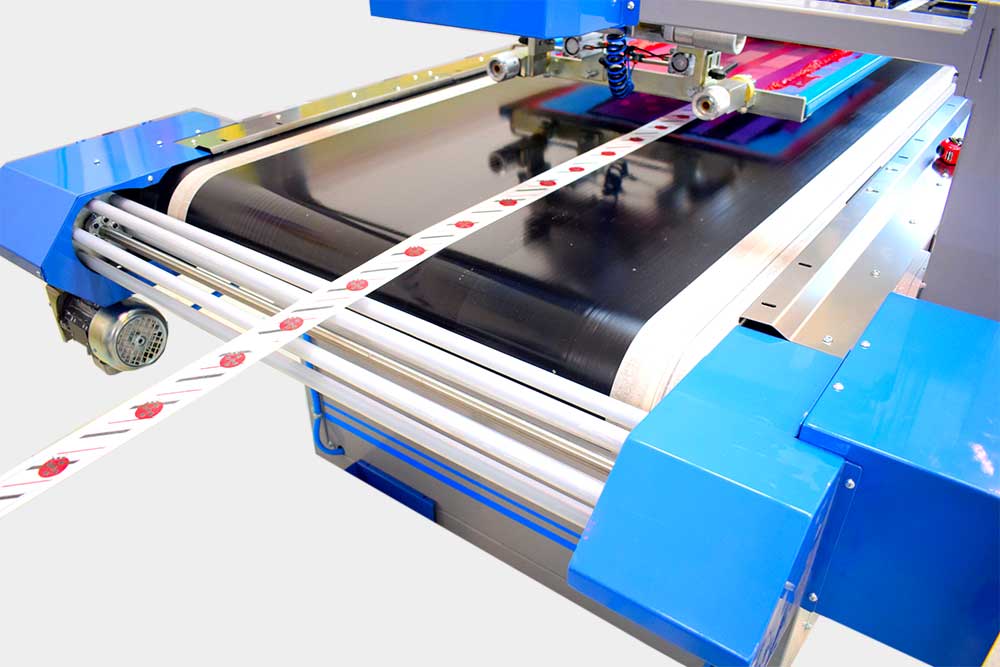

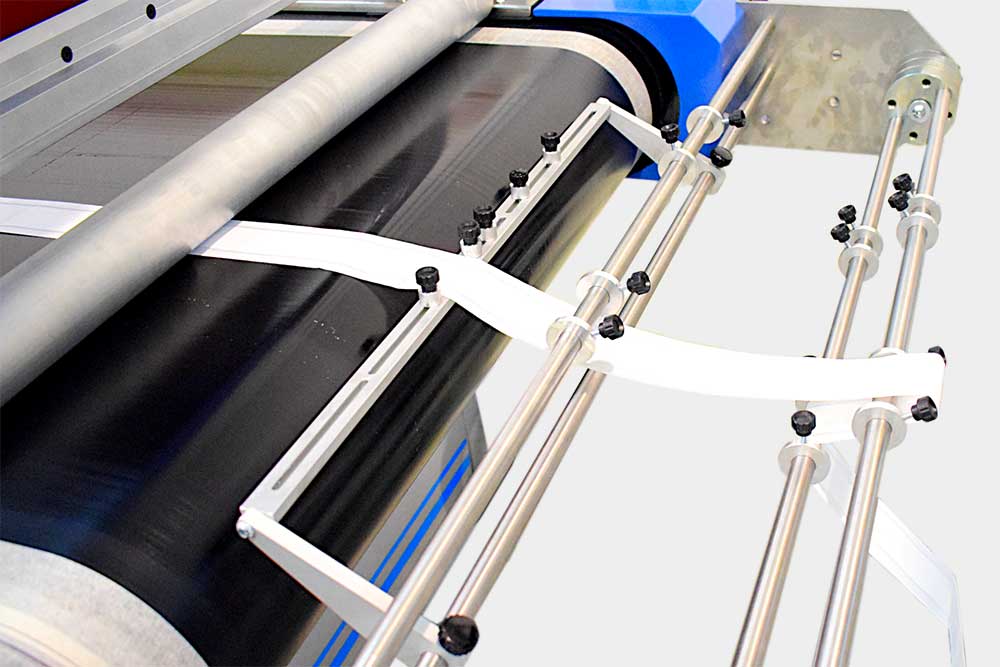

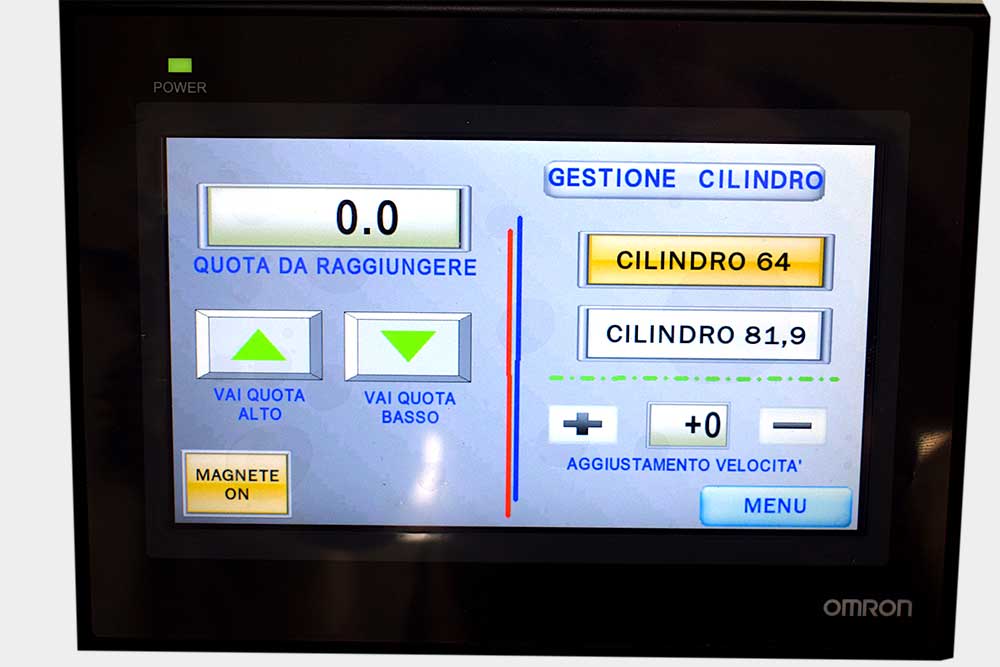

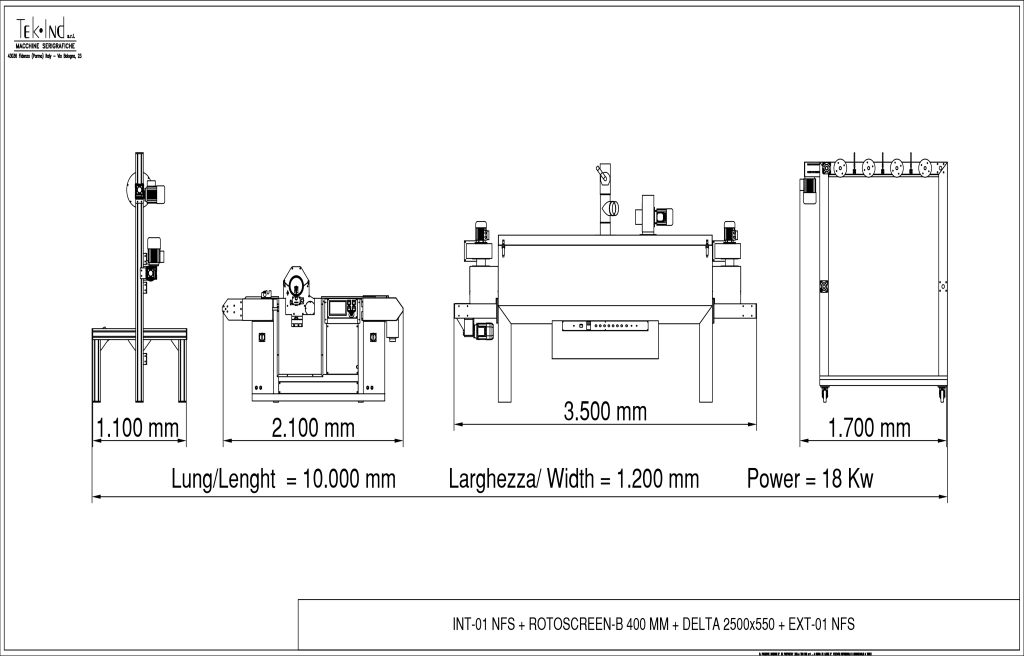

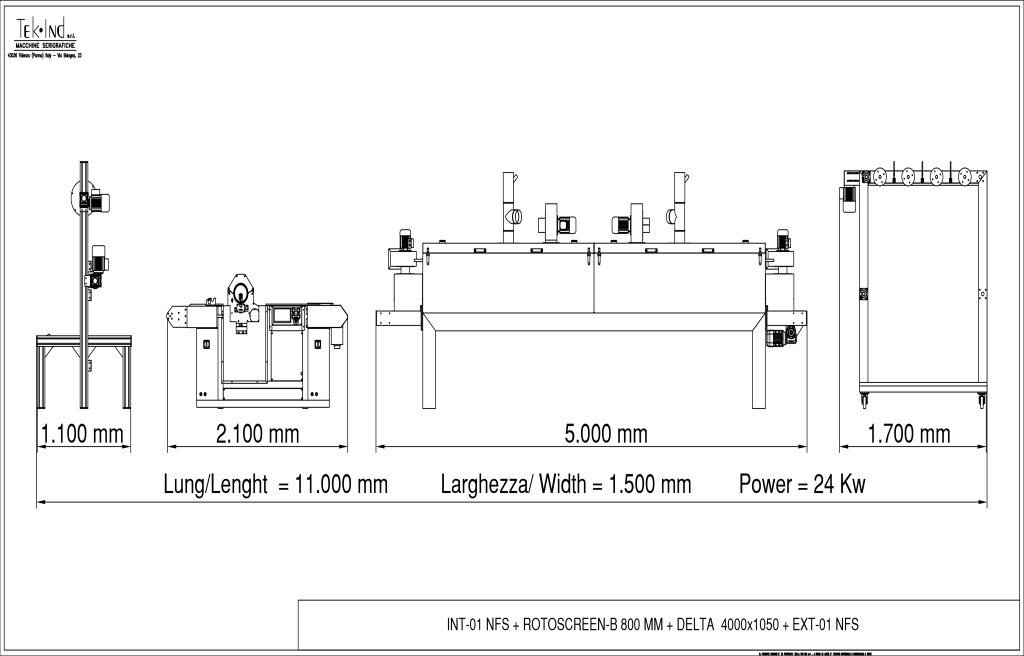

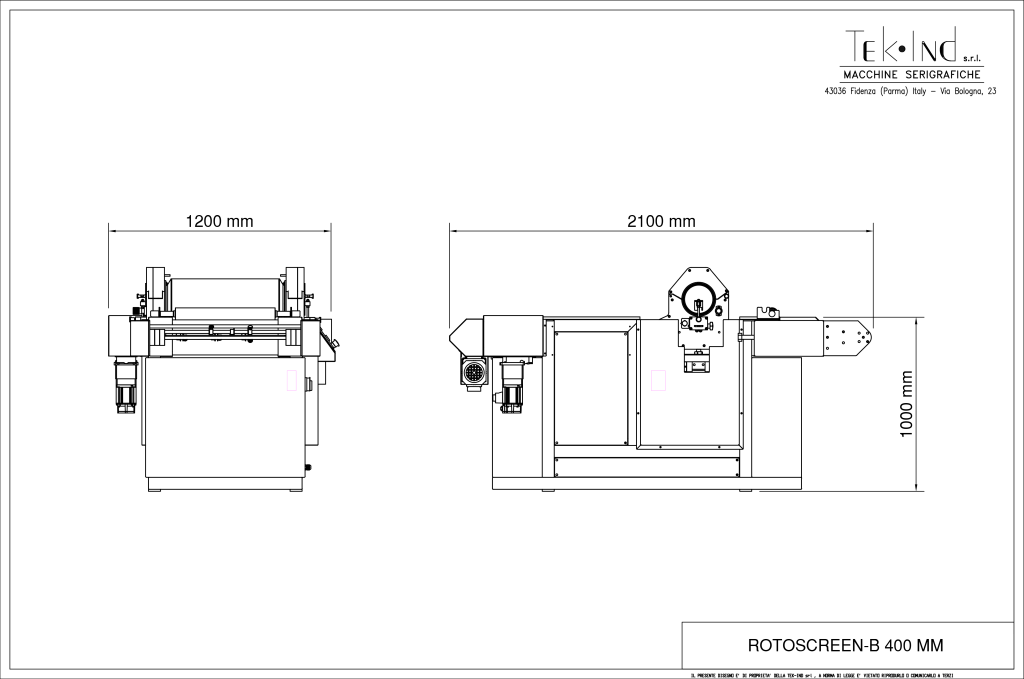

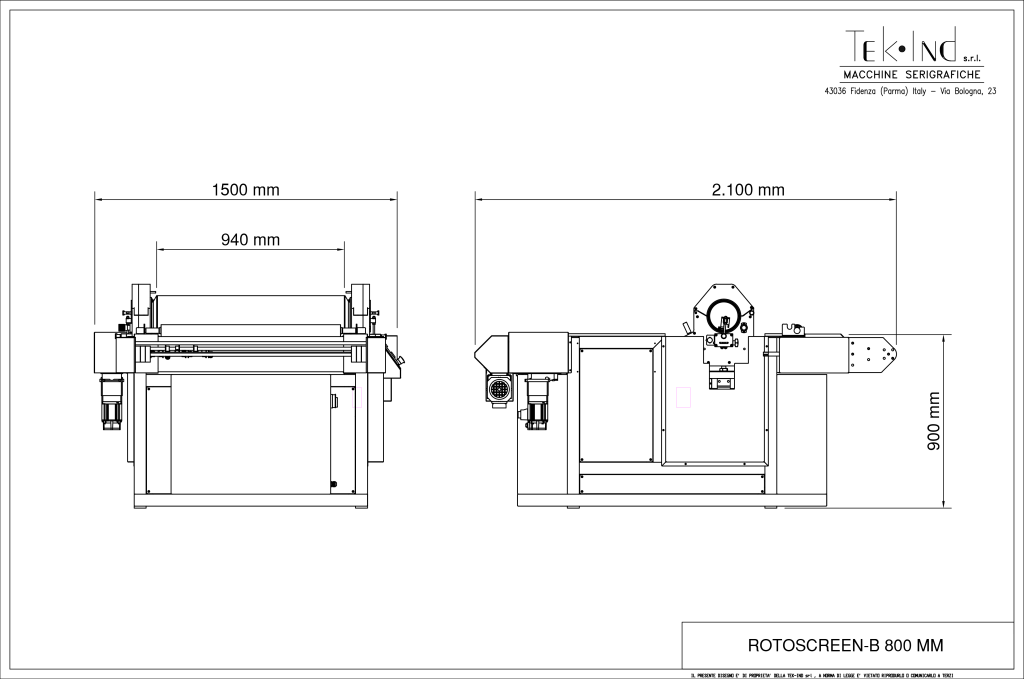

Rotoscreen: in its version complete with adhesive belt for printing both rigid and elastic ribbons, it is available in the following print formats: 400 mm; 800 mm; 1200 mm; 1600 mm, it is possible to mount cylinders with a circumference of 640 mm and 820 mm. It can handle multiple ribbon’s rolls simultaneously. The printing can take place in two different ways: with the Teflon squeegee or iron rod of various diameters with magnetic attraction on the printing cylinder, which positioned below the belt. It has a double inlet bar that allows adjusting the tension of the ribbon before it stick on the carpet, in output, it has a shaker that facilitates the detachment of the tape from the adhesive belt. The Rotoscreen printing machine with belt, requires an introduction INT-01, an oven for drying the ink Delta and one exit to boxes EXT-01.

Features:

- Printing Technology: Rotative printing with Cylinder

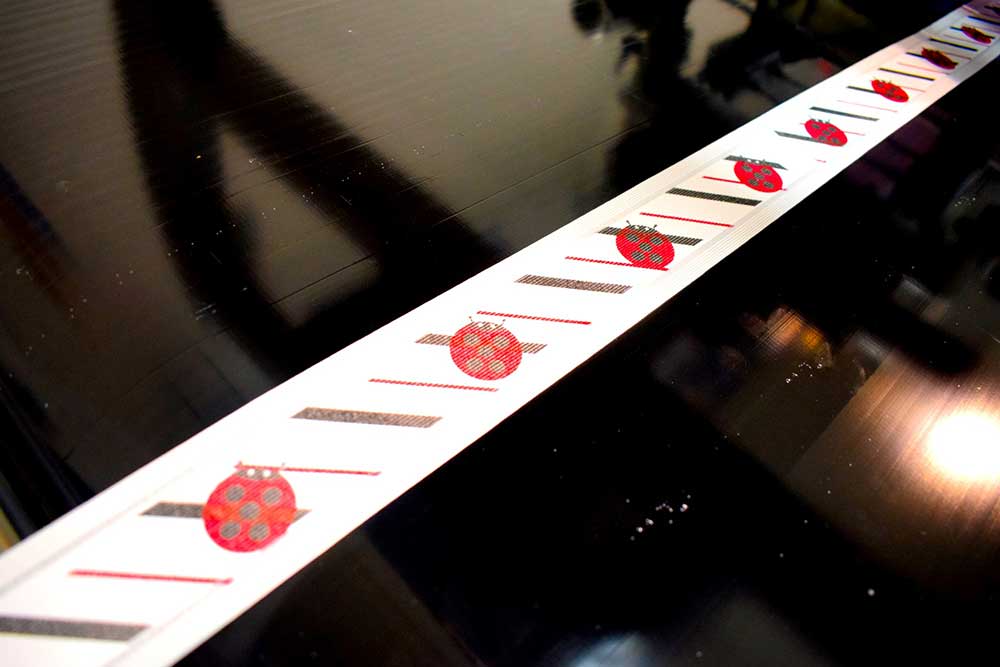

- Printing Typology: Monocolour rotative printing, ideal for continuous graphics

- Printable Narrow Fabric: Rigid narrow fabric, Elastic narrow fabric

- Mountable Cylinder: 640 mm / 820 mm

- Printing Width: 400 mm / 800 mm / 1200 mm / 1600 mm

- Production Capacity: 15 MT/min MAX

- Installed Power: 2.5 kw Without Magnet; 3.5 kw With Magnet

- Air Consumption: No needed Compress air

- External Sizes: Rotoscreen-B 400 (1200mm × 2100mm × 1300mm) (W×L×H) Rotoscreen-B 800 (1600mm × 2100mm × 1300mm) (W×L×H) Rotoscreen-B 1200 (2000mm × 2100mm × 1300mm) (W×L×H) Rotoscreen-B 1600 (2400mm × 2100mm × 1300mm) (W×L×H)

- Usable Inks: Water base inks, plastisol inks, silicones

- Complementary Equipment: Introduction(INT-01), Dryer(Delta), Guided exit(EXT-01), Silicon Pump (SP-Series).