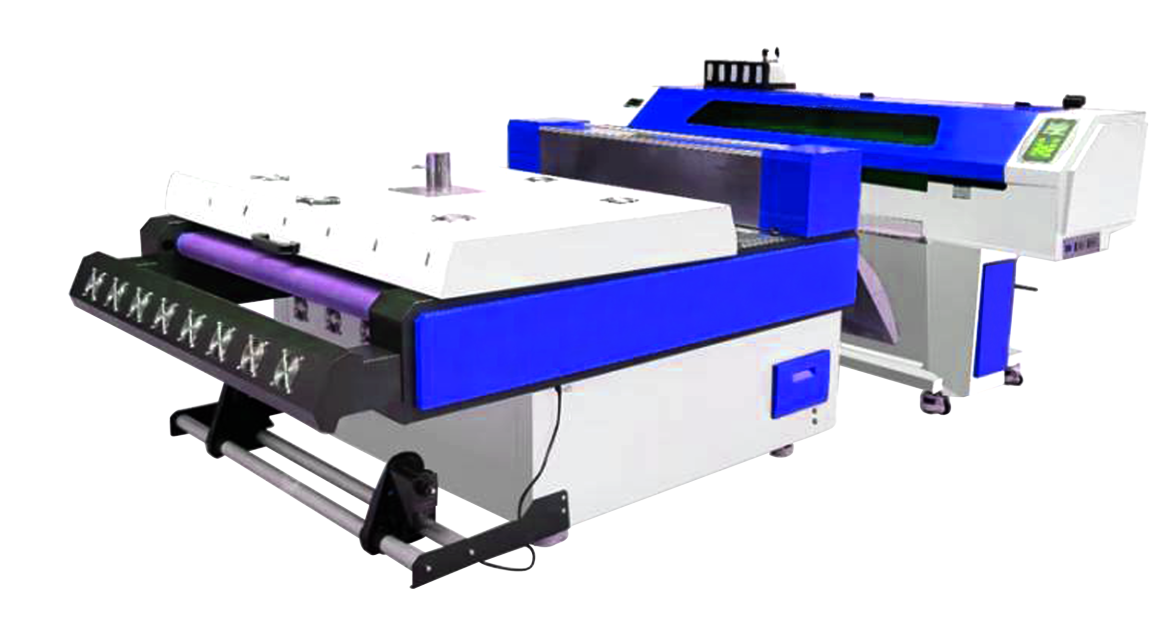

Digital DTF Printer

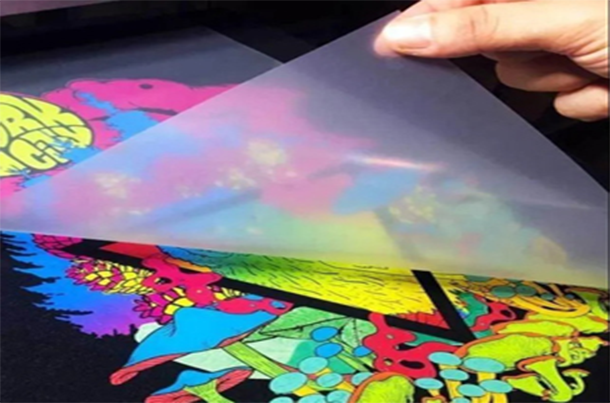

Application

Applied to heat transfer of various materials of clothing, personalized T-shirt production, team uniforms, work clothes, class uniforms, jerseys, bags etc.

Features

Automatic In-Line Cleaning System

Support automatic nozzle cleaning at regular intervals. When the printer is online, it automatically load ink and clean automatically, which not only helps reduce overall maintenance costs, but also saves time through automation.

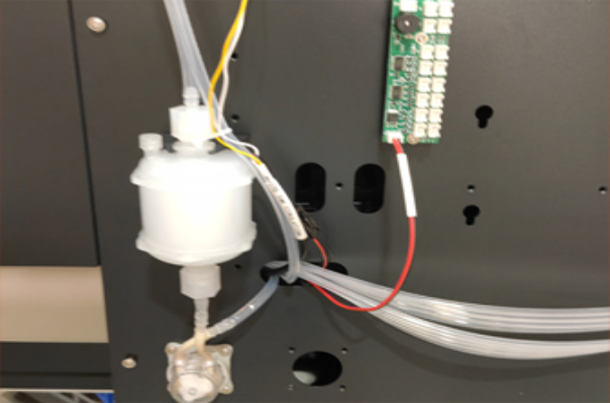

Automatic In-Line Moisturizing System

In order to prevent ink from clogging the nozzle, the ink cap will eject some moisturizer every once in a while to keep the nozzle clean and moist. This is the automatic in-line moistening system. Which can keep the printer nozzle in the best working state, avoid blocking the nozzle hole due to volatilization of solvent, and prolong the service life of the nozzle.

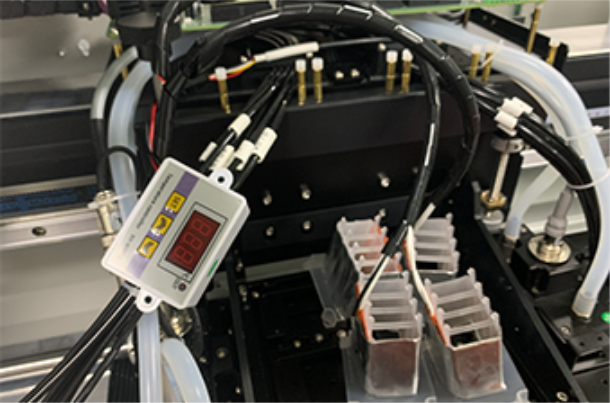

Ink Damper Heating Available

Ink damper device with external heating function. Since the heating unit is installed on the outside of each ink damper. With this technology, the printer can work normally in the environment with large temperature difference. In the printing process, the heating function can ensure the good fluidity of the ink.

White Ink Circulation & Filtration System

Our imported filter not only effectively intercepts large particles, gels and other impurities. But also allows the required pigment dyes to pass through and remain in the ink. The imported filter has excellent impurity filtering ability and longer service life.

Nozzle Compensated

The original Nozzle compensated technology can solve the problem of missing printing. Through this technology, the printer can automatically monitor the printing process. If the lines are discontinuous and there are blank areas, the nozzle will spray again to fill up the missing areas to ensure the output of a perfect picture.

Sublistar Mainboard

Different from the mainboard functions of other companies. the one independently developed by Sublistar can provide customized functions according to the needs of customers.

Integrated Purifier

Integrated purifier for the option to replace of exhaust pipe make the use of the machine more convenient.

Smart PLC Touch Screen

Equipped with an easy-to-use touch screen. Navigate the menu by simply touching the desired option.

Front, Middle, Rear Heating Devices

The worktable of the new generation DTF printer is equipped with heating devices in the front, middle and rear directions, which can ensure that the printed pattern becomes dry instantly.

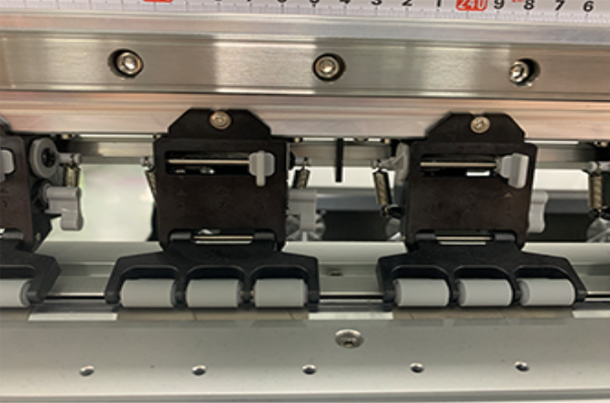

Pinch Roller Adjustable

According to the printing material, adjust the platen support to adjust the pressure of the pressure roller to ensure smooth paper feeding and improve the effect. Which can increase the friction force during paper feeding, make the process more stable and reliable, and avoid indentation and other phenomena during printing. It ensures high printing accuracy during printing and output.

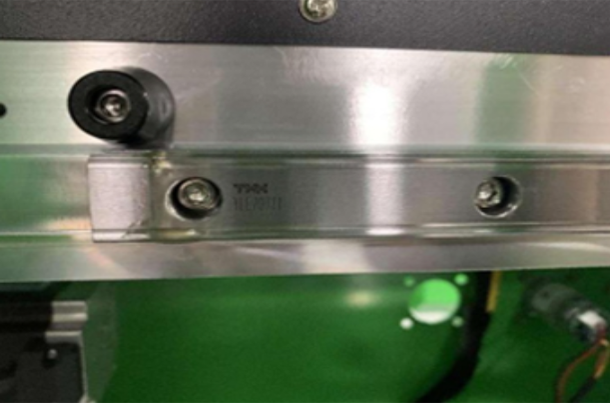

THK Mute Linear Guide

Stable operation and low noise. The friction between the sliders of the silent guide rail is greatly reduced, and the retention of lubricating grease is improved, thus achieving low noise, high speed, long service life and long-term operation without maintenance.

MPM (Multi-Printer Manager)

One computer can control multiple devices, and different IP manage printing. MPM (Multi Printer Manager) enables one computer to manage multiple printers, helping workers to control machine production more quickly and further improve production efficiency.

CCD Camera

High-resolution pixel cameras capture nozzle conditions in time during printing. The bound mobile APP will prompt synchronously. This great technology allows you to know the state of the printer at any time. It can reduce the production process, improve the production efficiency, cut down the defective rate and the cost.

Tension Feed/Take-up Reel

The paper feed and take-up with tension system allows you to complete production unattended for a simple and precise workflow from printing to loading and feeding through the roll-to-roll securely wound.

Suction Conveying System

Vacuum adsorption conveying platform, absorbing the print material to ensure that the material does not bulge or run off.

Infrared Drying

Adjustable temperature infrared and heating drying improves and protects color reproduction.

Technical Parameters:

| Model | TX-D-002 S iii | Voltage | AC 110V +/-10% | |

|---|---|---|---|---|

| Print Head | 2-3 Epson i32100 | Power | 200W – 450W | |

| Print Resolution | 4 pass: 12 sqm/h 6 pass: 8 sqm/h 8 pass: 6 sqm/h | Operating Environment | Temp: 20°C – 35°C, Humadity: 35%RH – 65%RH | |

| Ink Types | Water base ink, Dye ink, Sublimation ink | Dimension | 1766 x 750 x 1513 mm | |

| Ink Capacity | 5 color: 1.5 Lx/color | Height of Worktable | 1062 mm | |

| Media Width | 620 mm | Package Size | 1880 x 1060 x 740 mm | |

| Media Thickness | 1.55 to 6 mm (adjustable) | Net Weight | 190 kg | |

| Interface | Network Port | GrossWeight | 210 kg | |

| RIP Software | Maintop 6.1, Photoprint, Print Factory | |||