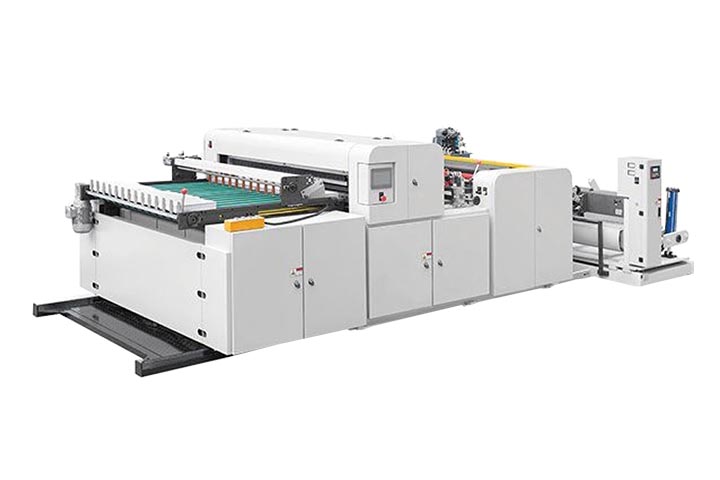

High-Speed Slitting Machine

Application:

This machine is suitable for cutting all kinds of paper, self-adhesive, paper plastic composite, film, OPP, PVC, pearlescent film, film composite, color printing composite, non-woven fabric and other large drum packaging materials. The machine adopts servo motor to control fixed length cutting. The transmission system adopts centralized control of pneumatic and photoelectric sensors. The machine integrates light, electricity and gas. It has the advantages of simple operation, high cutting precision, mechanical stability and low noise. (optional for pneumatic feeding) motor frequency conversion speed regulation, automatic counting, alarm and shutdown, and automatic tension adjustment of magnetic particle taper. At present, it is an ideal equipment for high quality large coil cutting in China.

Features:

- Frequency conversion speed regulation, Panasonic PLC touch screen control system, automatic counting, automatic length setting, alarm parking, automatic control and other functions.

- The frame adopts 16mm steel plate structure, the cross-cutting cutter base adopts cast heavy structure, and the guide roller adopts dynamic balance aluminum alloy guide roller.

- The drive positioning traction adopts the servo system drive shaft structure, and the feeding traction mode is that the motor drives the sprocket to drive and traction the rubber shaft.

- This machine is an ideal transverse and longitudinal cutting equipment, with high precision, high speed and smooth material receiving.

Technical Parameters:

| Model | TX-HQJ-1100 |

|---|---|

| Max Diameter of Raw Material | 1400 mm |

| Max Cutting Width | 1100 mm |

| Cutting Length | 20 – 1500 |

| Cutting Speed | 20 – 150 times |

| Horizontal and Vertical Accuracy | ± 0.2 mm |

| Total Power of Power Supply | 6 kw |

| Machine Weight | 2000 kg |