Hot Melt Powder Coating Machine

Application:

Hot Melt Power Coating Machine is applied to transfer printing products such as clothing trademarks, Ironing, wallpaper, paper, PVC and film, etc. hot-melt power spraying process.

Features:

- Thermoplastic polyurethane machine is after-printing corollary equipment, which substitutes for rendition products like logo, ironing, wallpaper, paper, and film.

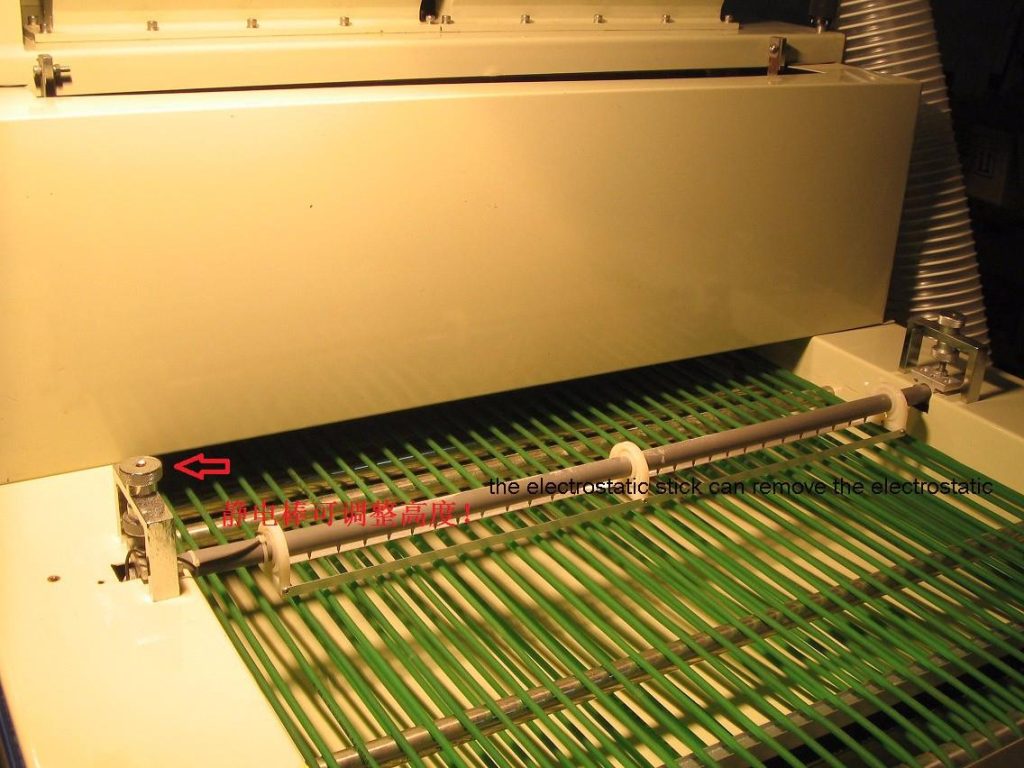

- It can powder and recovery residual powder incomplete processing. It has the advantage of easy to use, flexible adjustment, high efficiency, and not just pollution.

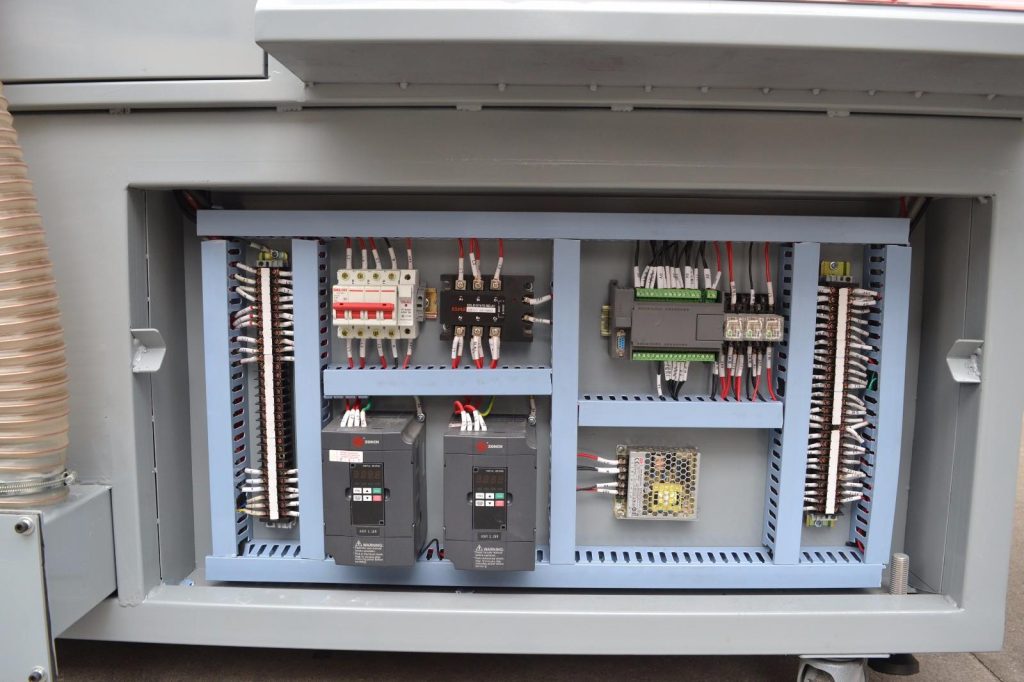

- All the transmission parts in the machine can achieve variable speed and be connected to the auto screen printing machine or gluing machine.

- It works well even with those paper film and wallpaper that have high demands. If necessary, it should be connected directly to drying equipment or UV light curing equipment.

Technical Parameters:

| Model | Total Power | Convey Belt Width | Powdering Width | Paper Thickness | Overall Dimension (mm) |

|---|---|---|---|---|---|

| TX-SF80S | 4.1KW, 380V | 800 mm | 650 mm | 1~5 mm | 2200 × 1800 × 2000 |

| TX-SF100S | 4.1KW, 380V | 1000 mm | 900 mm | 1~5 mm | 1000 × 700 × 2020 |